Pwm

Peb muaj ib qho kev xuas nrig ntaus, sib xyaw xuas nrig ntaus, thiab nrawm nrawm sib raug cov pwm kom tau raws li cov neeg xav tau ntawm cov neeg muaj lub cev muaj zog thiab cov rotors. Txog 90% ntawm pebKev Tsav Lamints yog customized los ntawm kev kos duab. Thaum lub sijhawm pwm tsim qauv, peb cov kws tshaj lij kev kos duab yuav kos duab rau cov lus qhia kom zoo dua cov neeg siv khoom zoo dua.

Kuaj cov qauv

Peb tuaj yeem ntsib qhov sib txawv thiab thev naus laus zis ntawm lub cev muaj lub cev muaj hnub lamination ua piv txwv.

A

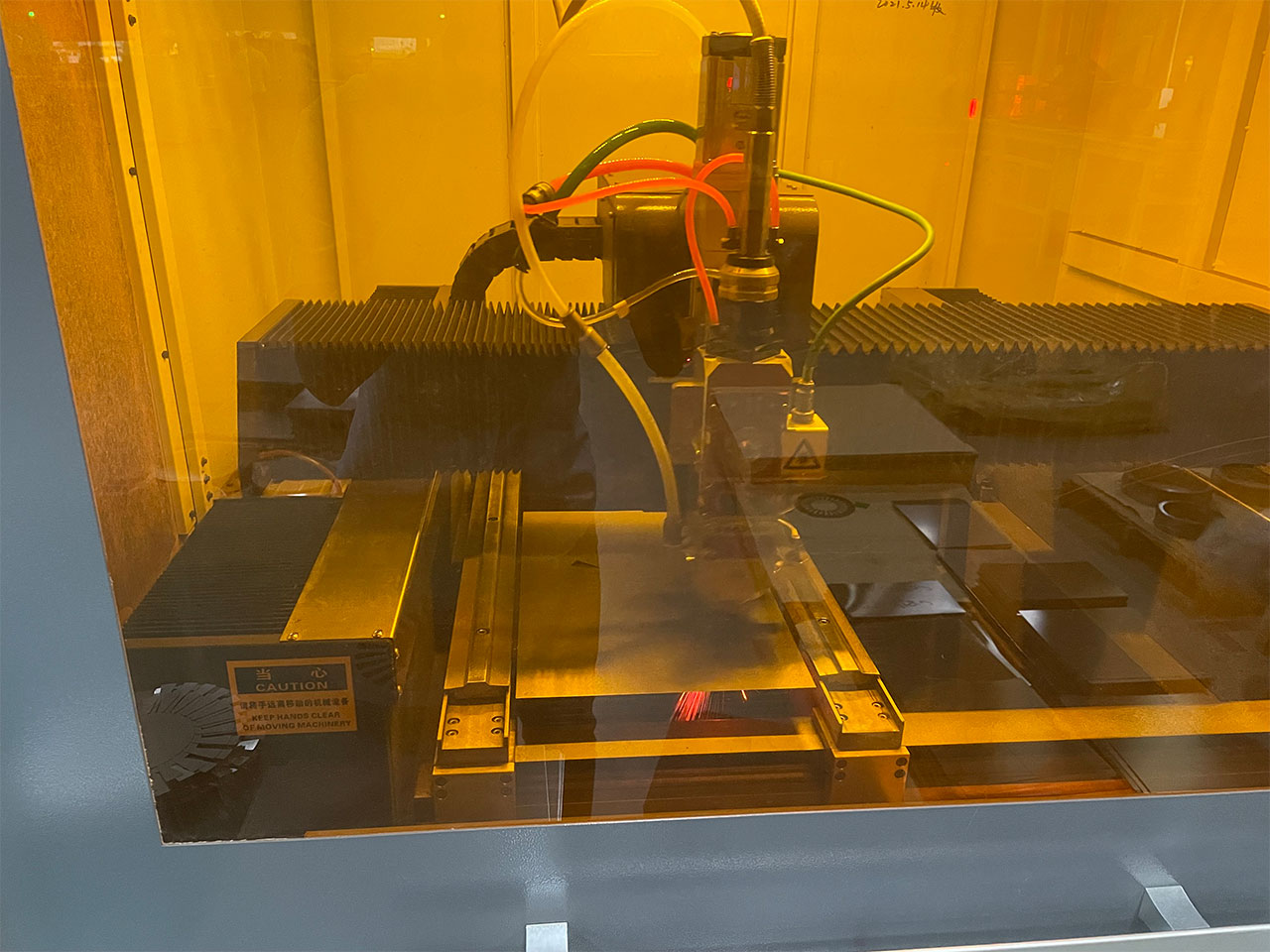

Laser txiav

C

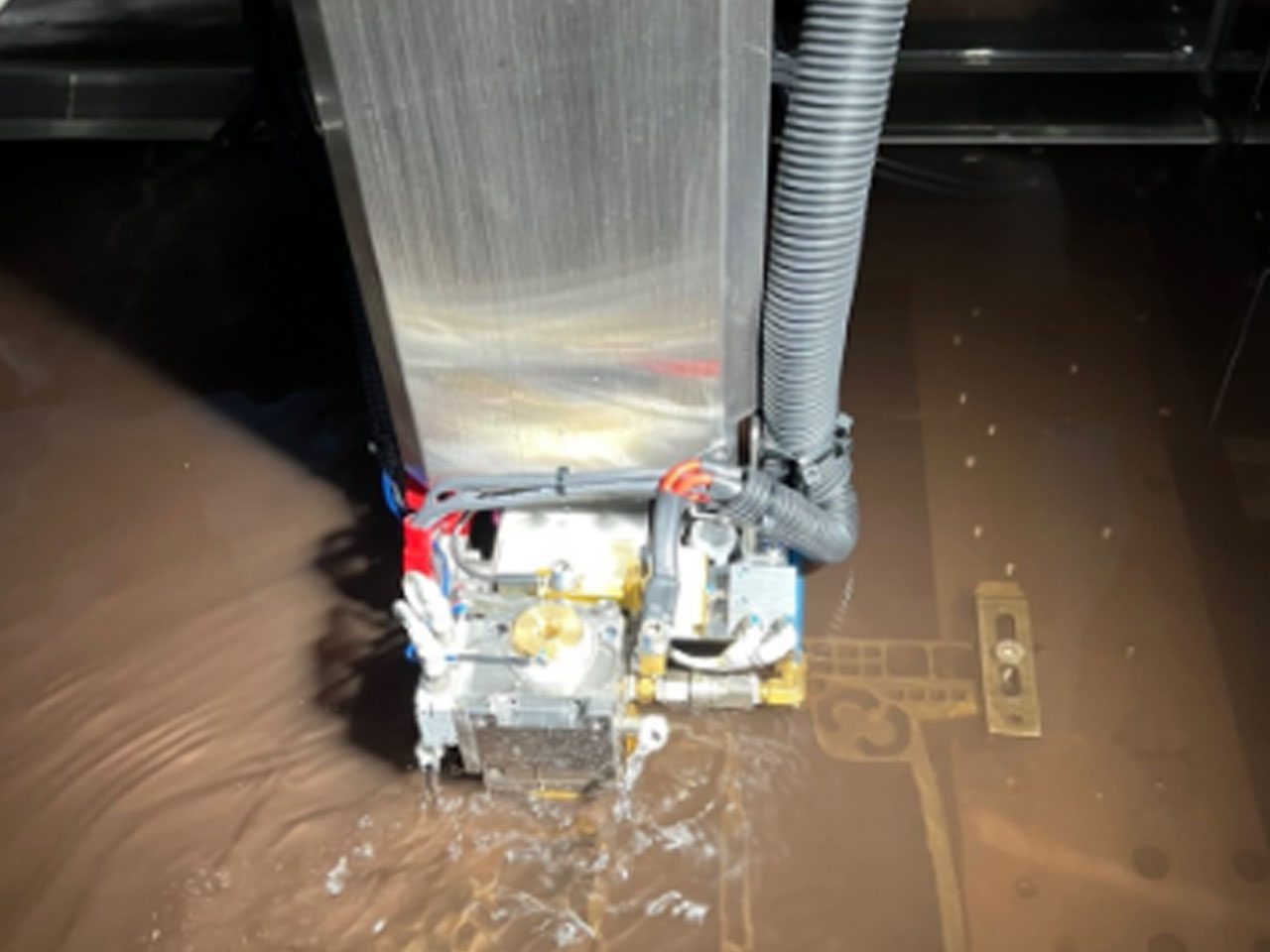

Kev Kub Ceev Hlau Txiav

B

Nruab Nrab Ceev Hlau Txiav

D

Tsawg Ceev Hlau Txiav (Peb imported lub seibu hom tshuab los ntawm Nyiv)

Tau luam tawm

Peb muaj ntau hom presses kom tau raws li koj cov kev xav tau sib txawv.

Ib lub vias stamping

Presses: 10T-16t

Compound Stamping

Presses: 40T-550T

Zuj zus mus(Kev Kub Ceev)Tau luam tawm

Presses: 630T, 550t, 315t (Schuler),300t (Aida),160T, 120t, 80t (nidec)

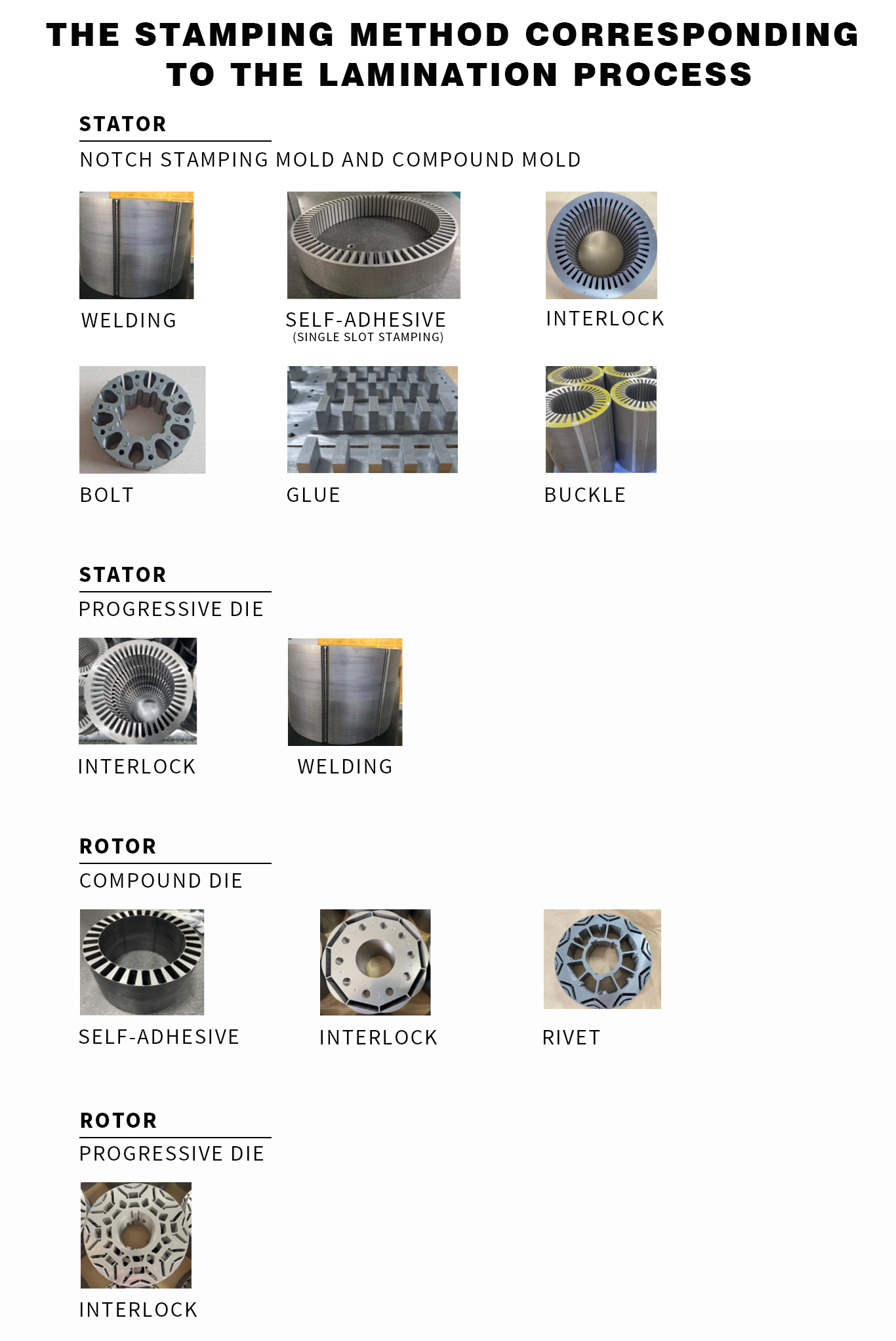

Stamping Rhiav & kom tau

↓

A.Qhov kev kawm qib schuler khoom & thev naus laus zis los ntawm lub teb chaws Yelemeesthiab Aida, Nidec los ntawm Nyij Pooj,uas qhia rau peb hauvKev Tsav Lamintskev lag luam ua qib tam sim no.

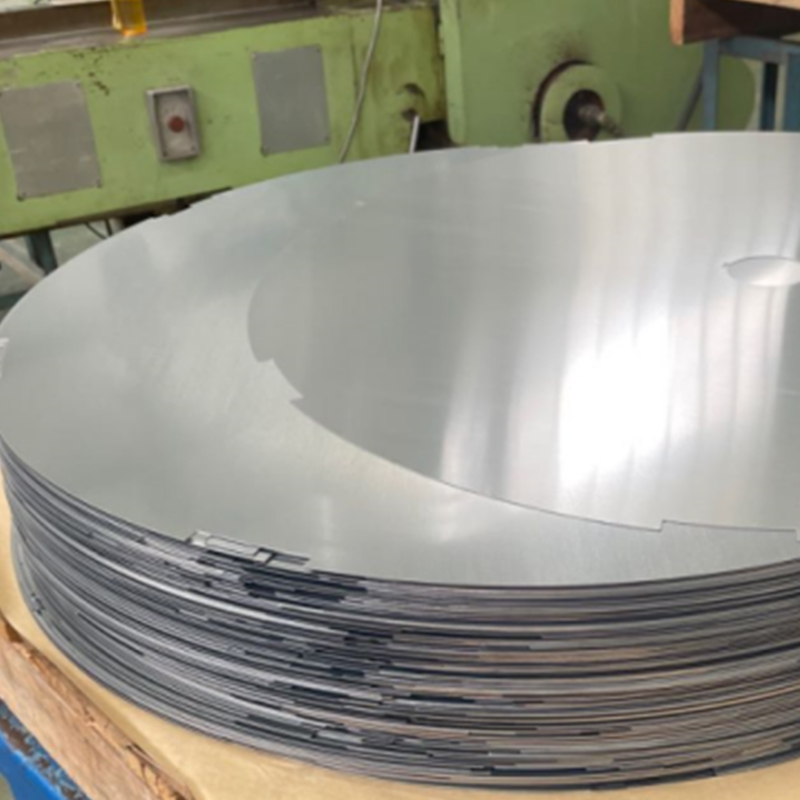

B.Cov pob ntau lawm ntawm 0.1 hli thickness silicon steel thiab 0.03mm tuab tsis-alloy khoom siv nyiaj.

C.The ib lub qhov xovxwm ib qho tuaj yeem tuaj yeem siv tau Od2000mm Max.

Ib lub vias stamping

Tuam: MECH Stamping tuag

Txiav cov ntawv silicon steel kom tsim nyog qhov loj me, thiab txhua daim ntawm lawv yuav ua ib tus zuj zus uas yuav tsum tau ua. Ib lub vias chav nyob yog ib txoj hauv kev haum rau cov stator Lamination nrog loj dua txoj kab uas hla thiab ntau ntau ntawm cov qauv.

Compound Stamping

Tuam: Compound Tuag

Kev yuav cov qauv silicon steel sawb raws li qhov loj me ntawm cov khoom lag luam uas yuav tsum tau, thiab tom qab ntawd tsim lub cev lamination thiab rotor lamination. Muaj ob txoj kev pub mis noj, ib qho yog siv Wafer punched los ntawm lwm lub cev lub cev muaj zog, tab sis tuaj yeem txuag cov nqi cov nqi; Lwm tus yog kev pub ua tas li ntawm ib daim hlab, nrog high efficiency.Peb yuav tshuaj xyuas qhov kev txiav txim siab los ua kev cog lus rau lub cev muaj zog rau lub cev muaj zog rau lub cev muaj zog rau lub cev muaj zog rau lub cev muaj zog. Ib qho ntxiv, peb lub tuam txhab muaj patent ntawm tus kheej los ntawm compound pwm, uas tau txo tus nqi ntawm cov theem thaum ntxov ntawm kev hnyav tuag batch stamping.

Txhim Kho Stamping

Tuam: Kev Loj Hlob Tuag

Hom pwm no tseem hu ua MOB siv hluav taws xob qib siab. Txawv los ntawm cov khoom sib xyaw pwm, nws tsuas yog siv cov khoom haum dav rau kev pub mis, ua tiav cov pwm thiab tus kheej hauv cov pob zeb ncaj qha los tsim lub stator thiab rotor stand.

Muaj ob hom kev cuam tshuam nws tus kheej. Ib qho yog cov kev sib tw ntawm tus kheej sab laj rau qhov loj me me ntawm lub cev muaj zog, uas muaj cov kev xav tau siab. Cov stacks tsis tas yuav tsum tau nias ob zaug ntawm lub tuam txhab toolte.Qhov lwm tus yog lub teeb lub ntsej muag sib dhos, uas yuav tsum tau nrawm dua.

Tus Phab Hlau Sib Tw

Peb muab cov xaim hluav taws xob puag ncig thiab cov pob zeb me me hauv theem piv txwv yog 150-400 hli, sab nraud ntawm cov khoom lag luam cov khoom lag luam tshwj xeeb yog tsis sib xws. Theem 5-50 teev / Hnub.

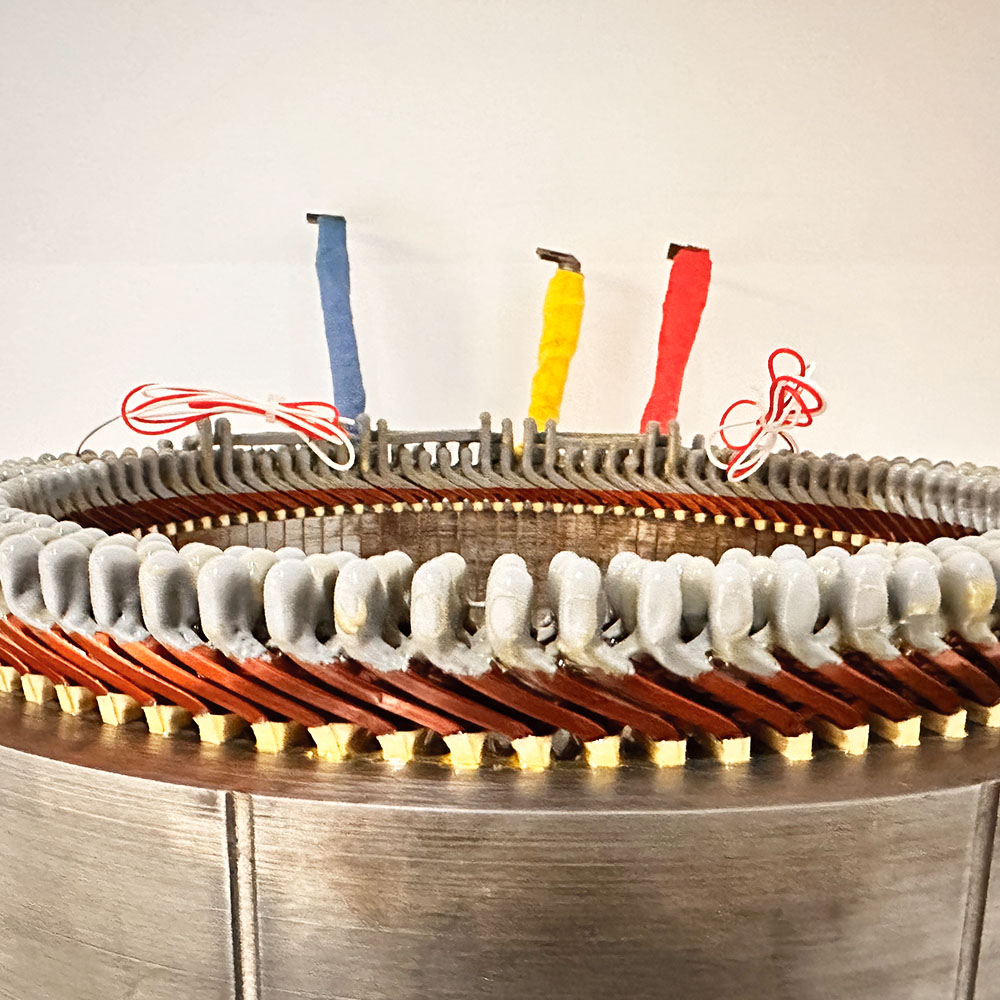

Pawg

Lub lamination yuav muab tso rau hauv Cores los ntawm Rivet, sib tw, thiab lwm yam siv tau ob qho tib si siv ob tog

Rivet

Rivet stacking feem ntau siv rau rotor, muaj lub taub hau rivet thiab tiaj tus rivet.

Vuam

Vuam stacking yog siv rau stator laminations, muaj laser vuam thiab tig vuam.

Muab lo

Xim kua nplaum rau txhua tus neeg lub cev muaj lub cev muaj lub cev muaj zog thiab lo lawv ua ke.

Sab laj

Ua rau cov ntsiab lus sib tshooj thaum lub sijhawm stamping, lub cev muaj zog yuav muab pawg rau Cores los ntawm lawv tus kheej nrog cov ntsiab lus no. Interlock yuav yog duab plaub lossis puag ncig. Kev ua haujlwm stamping tag nrho cov txheej txheem siv kev sib tshuam los cawm tus stator thiab rotor pawg nqi thiab lub sijhawm.

Tus kheej-nplaum

Cov Khoom Siv: B35A300-Z / B50A400-Z

Cov khoom siv tau txheej ntawm nws sab, nws yuav yaj thiab muab txhua lub rotor thiab stator lamination ua ke thaum cua sov. Tus kheej-nplaum yuav ua rau cov khoom lag luam smoother thiab ntau tawv.

Tus ntsias hlau

Bolt feem ntau yog siv rau cov stator laminations nrog loj dua cov taub.

Khawb siv tawv

Cov starding yog siv rau stator lamination, muaj ncaj ncaj lossis skew buckles.

Kev kuaj xyuas

Peb cov cuab yeej kuaj muaj xws li projector, kev sib koom tes, kev sib dhos testiv, thiab cmm muaj zeiss, hexagon, thiab wexel hom.

Kev tshuaj xyuas tau muab faib ua ib tsab xov xwm ua ntej, kev kuaj tus kheej, saib xyuas kev soj ntsuam thiab tshuaj xyuas zaum kawg. Tsis muaj teeb meem dab tsi ntawm lub stamping txoj kev yog, thawj ob peb daim ntawm lub cev muaj zog thiab thawj ob peb pawg yuav tsum tau xa mus rau chav kuaj xyuas, thiab ntau lawm tuaj yeem nqa tawm tsuas yog tom qab kev soj ntsuam dhau.

Yam ntim

Raws li cov neeg siv khoom, cov ntsiab lus thiab cov ringors tau ntim nrog cov thawv ntoo, thiab lwm yam ntoo, daim txhuam cev thiab daim txhuam cev, thiab lwm yam.

Thaum lub tsheb muaj peev xwm tsim nyog muaj lub cev muaj peev xwm ua tiav thiab cov nqaj hlau ua tiav, peb yuav cais lawv nrog daim txhuam cev thiab ntim rau hauv cov ntaub ntawv tsis yog khaub ncaws tsis yog export.